concrete 7 day break test|7 day strength test results : sourcing This method involves breaking a sample of concrete, usually in the form of cylinders, to determine the maximum strength the concrete can endure. The test is generally implemented after a certain curing period, such as 7 days .

web1 dia atrás · 30/08/1968. LUIS CARLOS LABARCE. DEIXA VIUVA A SRA. ZILDA APARECIDA DE LIMA FARIA. 55. Cemitério Ana Rosa de Paula. Jaú - SP. 25/02/2024.

{plog:ftitle_list}

WEBShare your videos with friends, family, and the world

According to section 19.2.1.3 of ACI 318-19 the specified compressive strength shall be based on the 28-day test results unless otherwise specified in the construction documents. 3- or 7-day test results are used to monitor early strength gain, especially when high early-strength concrete is .Reading time: 1 minute. The standard concrete compressive strength test is carried out at 28 days. 3-days and 7-days concrete tests are carried out only to monitor the early strength gain .

ACI 318 does not appear to require the 7 day test.only the 28 day. However, I seem to recall that the 7 day is commonly specified to provide early warning of any problems . Concrete, by Mindness and Young, gives a general rule: The ratio of 28-day to seven-day strength lies between 1.3 and 1.7 and generally is less than 1.5, or the seven-day . A single seven-day-old cylinder breaks at 2,250 psi. The Architect says this is less than 70 percent of fc1 and the concrete strength is suspect. A 28-day test result is 3,150 psi and the. This method involves breaking a sample of concrete, usually in the form of cylinders, to determine the maximum strength the concrete can endure. The test is generally implemented after a certain curing period, such as 7 days .

concrete strength after 7 days

How to Get the Best Results from Concrete Core Testing - Understanding the factors that affect core testing results will help you achieve accurate in-place concrete strengths.This guide provides an introduction to the evaluation of concrete strength test results. Procedures described are applicable to the compressive strength test results required by ACI 301, ACI .• A 3 or 7-day test may help detect potential problems with concrete quality or testing procedures at the lab but is not a basis for rejecting concrete, with a requirement for 28-day or other age .

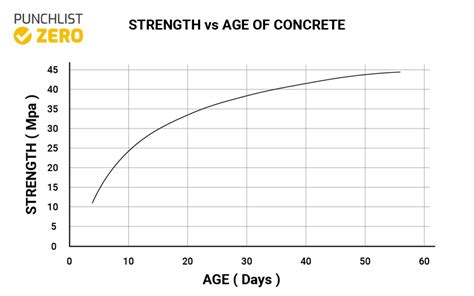

4000 psi concrete to MPa is about 27.6. The compressive strength of 4000 psi concrete is approximately 11 MPa (1600 psi) at 3 days, approximately 18 MPa (2600 psi) at 7 days, approximately 25 MPa (3600 psi) at 14 days, approximately 26.5 MPa (3840 psi) at 21 days and approximately 4000 psi at 28 days when tested with 15cm dia and 30cm length of cylinder of . Concrete Testing Six Most Common Causes of Low Cylinder Breaks . The most common solution is to wait and let your concrete continue curing, then test strength again on your next break day (that is, day 7 or 14). . Before the concrete reaches its intended 28-day strength, it passes through various stages of hardening. The 7-day strength test is one of the early indicators of how well the concrete will perform. The American Concrete Institute recognizes 28 days or “the test age designated for determination of the specified compressive strength.”5 Therefore, when a specifier calls for 5,000 psi concrete at 28 days, this tells the concrete producer to select a mix design that will attain a minimum of 5,000 psi 28 days after manufacture.

The owner paid for f'c = that specified at 28 days, not the 7 day break. The 7 day breaks are usually provided so as to allow intermediate information regarding form removal, application of loads, etc. as well as what you indicate - an indication of the expected 28 day strength. . C94 16.2 Tests of concrete required to determine compliance . Standard Test Methods. While compressive strength is a vital aspect of concrete performance, how exactly do we measure it? The answer lies in the standard concrete strength test method for assessing the strength of cylindrical concrete specimens, ASTM C39.This method involves breaking a sample of concrete, usually in the form of cylinders, to determine .Cast-in-Place Concrete.7 Some project specifications call for tests at a higher frequency, typically at one test per 100 yd3 of concrete. Table 1 shows how often the measured compressive strength test is likely to be below f′ c based on statistical concepts for testing frequency at one test per 100 or 150 yd3 of concrete.

I have a contractor that has repeatedly had 7-day and 28-day concrete cylinder breaks significantly lower than the specified strength. In a meeting on Friday, h . Per Chapter 5 of the ACI Building Code Requirements for Structural Concrete (ACI 318) A strength test is defined as the average strengths of TWO cylinders tested at 28 days. A .While concrete continues to gain strength after 7 days, around 65-70% of its 28-day strength is achieved at the 7-day mark. Testing of concrete cylinders or cubes at 7 days helps to verify that the concrete has gained adequate strength to allow form work to be removed, for post-tensioning activities to proceed, or to put the concrete element .

The American Concrete Institute (ACI) is a leading authority and resource worldwide for the development and distribution of consensus-based standards, technical resources, educational programs, certification programs, and proven expertise for individuals and organizations involved in concrete design, construction, and materials, who share a commitment to pursuing the best .

The specification for my job requires that the 28-day compressive strength of masonry be 2500 psi. If I make extra prisms and break them at 7 days, how strong do they need to be to assure that I meet this requirement? You need to establish the relationship between the 28-day strength and the 7-day strength.The compressive strength of M20 grade concrete varies between 17 and 23 N/mm2 (i.e. between 170 kg/cm^2 and 230 kg/cm^2) after 28 days curing. This means that the concrete can withstand a compressive load of 170 to 230 kg/cm² before it fails.. In compressive strength test of concrete cube the push force applied on the both faces of concrete specimen and the maximum . But some are made of metal which means they can be reused. The test itself can cost anywhere from to 0 to break a set of three concrete test cylinders. The Cons of Using Third-Party Concrete Testing Labs. Despite the benefits of using third-party labs for concrete cylinder testing, this method isn’t completely foolproof.

2 GUIDE TO EVALUATION OF STRENGTH TEST RESULTS OF CONCRETE (ACI 214R-11) Chapter 4—Analysis of strength data, p. 4 4.1—General 4.2—Statistical functions Publication: Concrete International. Volume: 32. Issue: 12. Appears on pages(s): 41-44. Keywords: compressive strength, 7-day strength, 28-day strength, laboratory testing. DOI: Date: 12/1/2010. Abstract: Probably the most common report in the concrete industry is the concrete test report. Typically, a report is sent when a 7-day break is .Why do we test concrete cylinder at 28 days? Concrete gains strength with time after casting. It takes much time for concrete to gain 100% strength and the time for the same is still unknown. The rate of gain of concrete compressive .Concrete international / December 2010 41 by Luke m. SneLL The Concrete Test Report What the designer needs to know Probably the most common report in the concrete industry is the concrete test report. Typically, a report is sent when a 7-day break is completed. Later, the same report is updated and resent with the 28-day test results.

Concrete Cylinder Break Testing. The compressive strength of hardened concrete is measured by pouring cylinders of fresh concrete and then measuring the amount of force necessary to break up the concrete at predetermined intervals throughout the hardening process.From above table, we see that, concrete gains 16 percent strength in one day, 40 percent in 3 days, 65% in 7 days, 90% in 14 days and 99% strength in 28 days. The American Concrete Institute. Founded in 1904 and headquartered in Farmington Hills, Michigan, USA, the American Concrete Institute is a leading authority and resource worldwide for the development, dissemination, and adoption of its consensus-based standards, technical resources, educational programs, and proven expertise for individuals .Section 26.12.6.1 states that if the likelihood of low-strength concrete is confirmed and calculations indicate that structural adequacy is significantly reduced, tests of cores drilled from the area in question in accordance with ASTM C42 “ Standard Test Method of Obtaining and Testing Drilled Cores and Sawed Beams in Concrete” shall be .

The 7-day strength is typically estimated to be 75% of the 28-day strength, but this relationship needs to be determined experimentally for each concrete mix. ACI 318-02 and ACI 301-99 provide standards for compressive strength testing of concrete cylinders at 7 and 28 days. At 28 days, the average strength of two cylinders must meet or exceed .The other samples may include a test at 3 or 7 days to estimate strength development and a "hold" cylinder if there are discrepancies in the 28-day tests. Initial Curing: Choose Wisely! In this sensitive period, the samples progress through initial and final sets of the concrete mix and begin strength development by hydration.

In depth overview of testing fresh concrete. Learn about concrete testing procudes including concrete slump tests. Find out what testing equipment is required. Get Job Leads Today! About Us; . 1 day at 100°F/27 in lab cure: 11: 8900: 3 days at 100°F/24 in lab cure: 22: 7800: 7 days at 100°F/21 in lab cure: 26: 7400: 1 day air/27 days moist . This paper presents a simple mathematical model to predict the compressive strength of concrete at 28 day from early age (say 7 days) results. . was based on the seven-day test results, and .

concrete strength after 28 days

So it’s obvious to test concrete on 28 days for strength. Concrete reaches 99% of its full potential strength in 28 days and 28 is also a round figure (4 weeks). Hence, it is chosen for the definition. Now, 3, 7, and 14 day are both round figure in terms of percentage of strength development and also round figure in weeks. Like the cylinder break test, the concrete cube test is performed for the purpose of determining the compressive strength of a concrete element. The cubes used for this test have a dimension of 150 x 150 x 150 mm as long as the largest aggregate does not exceed 20 mm. Generally speaking, the cubes are cured for and tested at 7 and 28 days .

concrete strength after 14 days

concrete strength 7 day 28

aggregate impact value test as per is code

webWe know that fine print can be painful, but we believe it’s important for you to have all the facts! (1) Prices valid from September 25th – 30th, 2023. Offer only applies to new lease .

concrete 7 day break test|7 day strength test results